| View previous topic :: View next topic |

| Author |

Message |

Sprintervention

Alfasud

Joined: 30 Jul 2004

Posts: 60

Location: York

|

Posted: Fri Mar 24, 2006 5:31 pm Post subject: Crank cross drilling Posted: Fri Mar 24, 2006 5:31 pm Post subject: Crank cross drilling |

|

|

I have taken one of my cranks to a friend that does some very interesting things with engines, he suggested that cross-drilling all the bearings may help with oil starvation issues at bearing No 1. He did, however, note that the webs are pretty thin and that it may be difficult to prevent breakthrough.

Has anyone tried this and was it a success, don't wan't to risk a crank trying it if there are no benefits.

Alternatively does anyone know any other ways of preventing oil starvation to the big ends? I think that there could be some improvements in the sump to be made, any suggestions?

Thanks

Chris |

|

| Back to top |

|

|

hugh jinjin

Alfasud

Joined: 04 Sep 2004

Posts: 68

Location: Glasgow

|

Posted: Fri Mar 24, 2006 10:08 pm Post subject: Posted: Fri Mar 24, 2006 10:08 pm Post subject: |

|

|

hi, I think that cross drilling the crank actually restricts oil flow to the big ends, and is done to prevent oil starvation to the mains. At least that is the theory as applied to mini race engines.

Narrowed 105 series big end bearings seem to be the choice for racing boxer engines. |

|

| Back to top |

|

|

Sprintervention

Alfasud

Joined: 30 Jul 2004

Posts: 60

Location: York

|

Posted: Fri Mar 24, 2006 11:27 pm Post subject: Posted: Fri Mar 24, 2006 11:27 pm Post subject: |

|

|

I think that the idea was to try and equalise the pressure across all bearings, no 1 big end is fed by the oilway from the front crank pin and that is furthest away from the pump.

The 105 series bearings make a lot of sense, the standard ones really aren't upto much, anyone know how they are narrowed without bearing contamination?

Thanks for the comments.

Chris |

|

| Back to top |

|

|

hugh jinjin

Alfasud

Joined: 04 Sep 2004

Posts: 68

Location: Glasgow

|

Posted: Sat Mar 25, 2006 11:03 am Post subject: Posted: Sat Mar 25, 2006 11:03 am Post subject: |

|

|

sounds reasonable Chris.

I have a set of 105 bearings in my engine, the guy I bought it from bought them already narrowed from Adie Hawkins @ ahmotorsports.

another point to think about when considering cross drilling is the nitriding of the crank. If you drill through that you may run the risk of a crack starting from inside the new oilway. I don't know if this is a factor but it is something I was a bit concerned about when trying to decide on what to do with my engine. |

|

| Back to top |

|

|

Sprintervention

Alfasud

Joined: 30 Jul 2004

Posts: 60

Location: York

|

Posted: Sat Mar 25, 2006 1:20 pm Post subject: Posted: Sat Mar 25, 2006 1:20 pm Post subject: |

|

|

Good point, hadn't considered that.

I don't know which cranks were nitrided but I believe that the 16V cranks were. For that matter which cranks, if any, are forged items.

Has anyone tried altering the oil flow in any other way other than cross drilling, oil pressure relief valve, plugging oil ways and redrilling etc.

Are there any aftermarket oil pumps or sumps etc?

Regards

Chris

_________________

1987 Alfa Sprint Veloce |

|

| Back to top |

|

|

knight

Guest

|

Posted: Tue Mar 28, 2006 4:35 pm Post subject: crank Posted: Tue Mar 28, 2006 4:35 pm Post subject: crank |

|

|

cross drilling the mains is normally done if the lower bearing is non-grooved (plain) as it will only have a 180 degree crank rotation to get the oil through to the big end......cross drilling then allows a consistent 360 degree flow of oil to the big ends.......but on the flat-4 alfa engines what sort of bearings do they run????.......if they are both grooved, then dont worry yourself about cross drilling........if one is grooved and the other plain, then you could argue its necessary, but how hard are you revving your engine?......I design engines for a living and I have designed several race cranks that rev to around 8500 to 9000 RPM, and cross drilling the mains was the normal thing to do on a race crank, as we run a grooved upper and plain lower, but they were really high revving.

you may be able to get another grooved bearing, bin the plain one and hey presto, two grooved bearings - job done

as for modifying a standard crank - I would be surprised to hear that the production crank is nitrided???.....its very expensive to do in a production environment......they are normally induction hardeded (for bearing wear resistance) and fillet rolled for the fatigue resistance.......if you drill into either a nitrided or induction hardened crank, which will be like drilling glass........ you will most likley create a nasty stress raiser, as most fatigue cracks start from the oil drillings.......I'm not saying it cant be done, just beware it sounds like a bodge to me.........as a start check what main bearings you are running, otherwise you will be wasting your time.

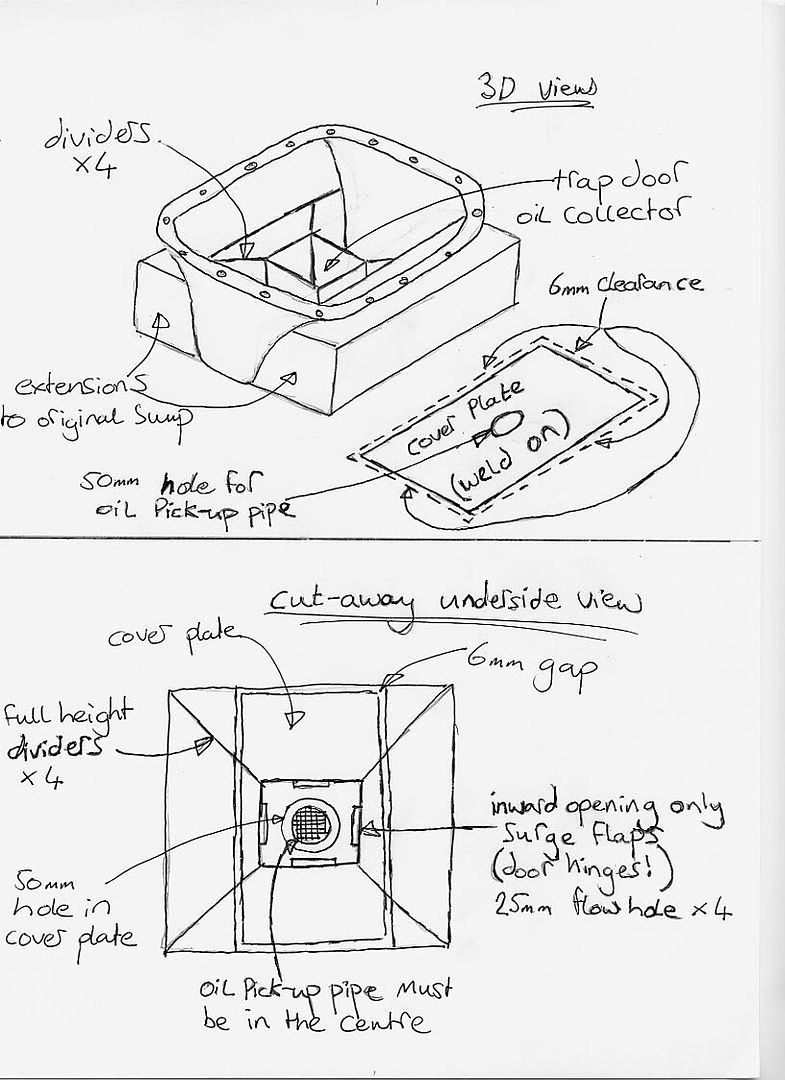

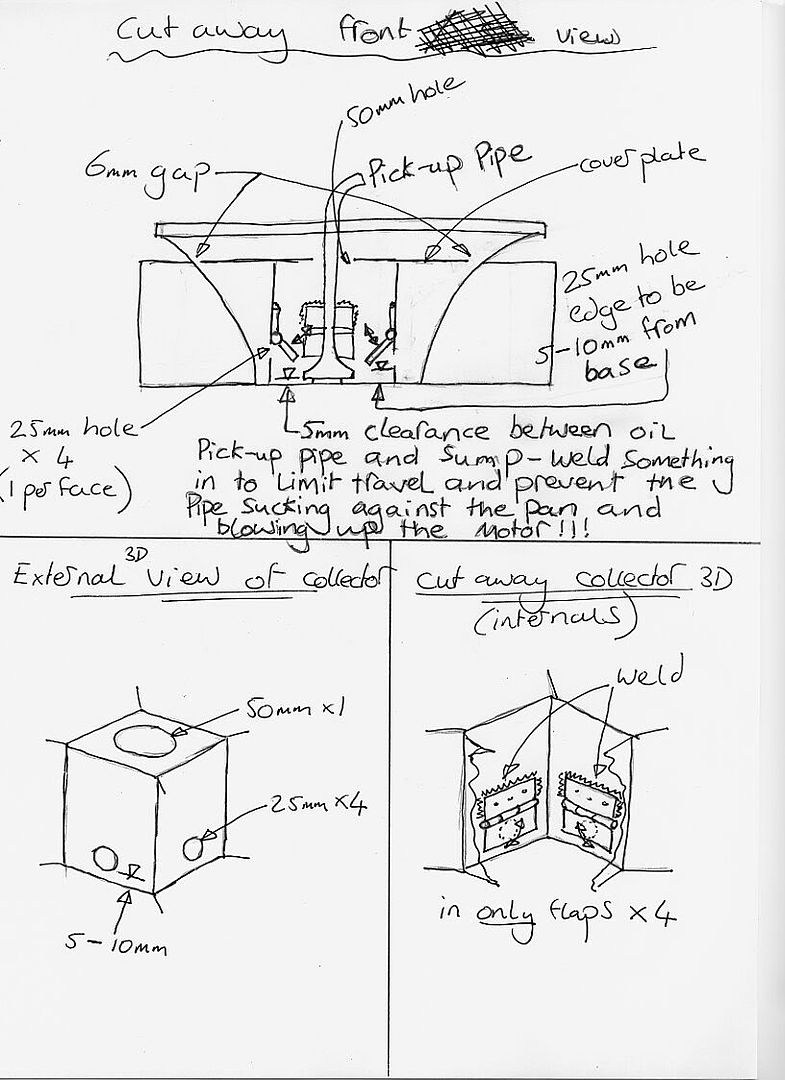

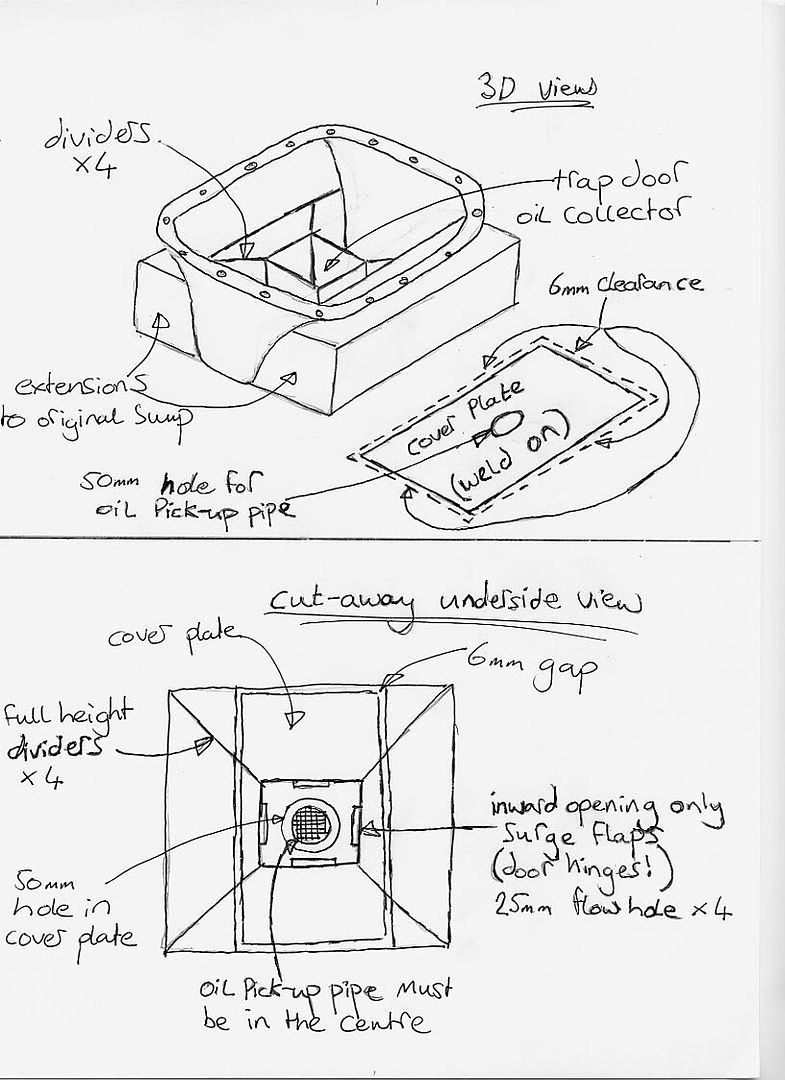

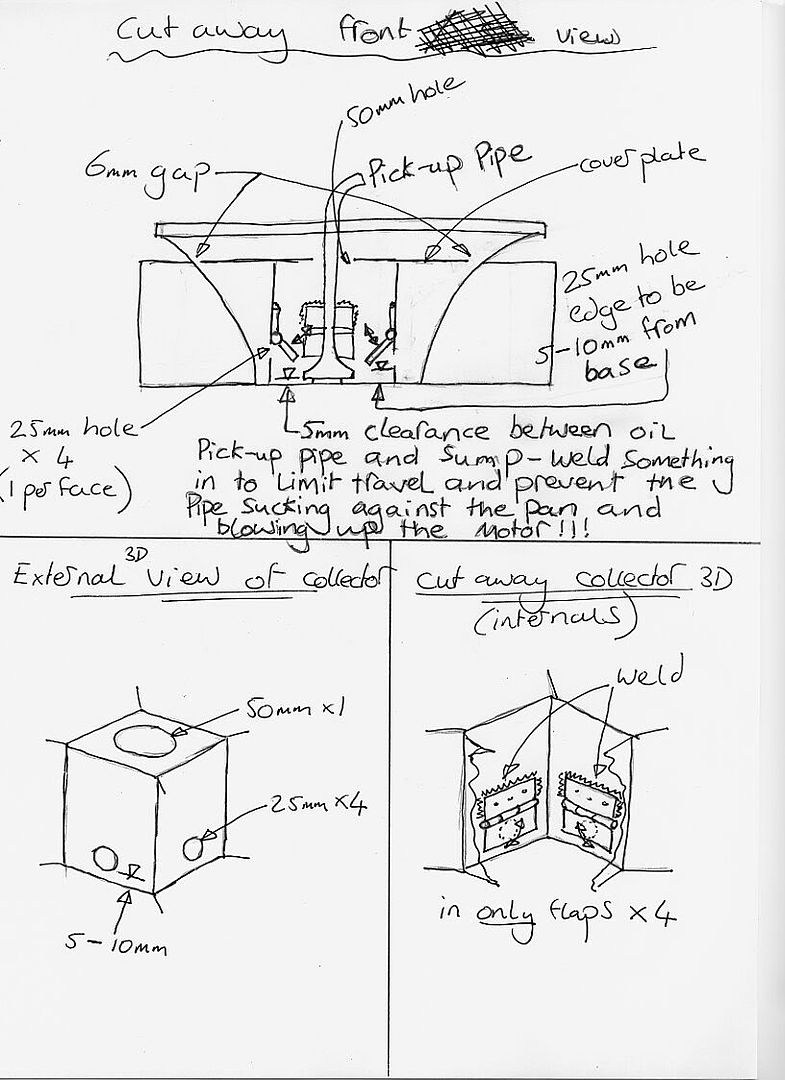

as for wet sumps, when done correctly they work fine, both BTCC and WRC cars still run wet sumps........you need a simple 4 trap door sump, which is basically a 5 x 5 inch box, with "in-only" oil flow control flaps (door hinges work fine!), all mounted around the centrally mounted oil pick-up pipe, dividers link each corner of the trap door box to each corner of the sump, so whatever your doing (breaking, accellerating, turning) each quarter of the sump will throw a chunk of oil at the pick-up pipe. you will also need to add a big lid to the entire sump, but leave 6mm clearance around all the edges, which will allow all the oil to drain from the cylinder walls back into the sump. also a hole for the pick-up pipe to protrude through!

also having looked at my 1.7 8v sump, I reckon you could also be doing a good thing by adding extra wings & volume to the sump sides in order to reduce the oil height and keep more oil in the sump for those extra long corners that tend to blow your engine up.......you may also want to add more volume to the front and rear?.......but the sides are deffo a priority!

hope that little lot helps  |

|

| Back to top |

|

|

hugh jinjin

Alfasud

Joined: 04 Sep 2004

Posts: 68

Location: Glasgow

|

Posted: Wed Mar 29, 2006 10:06 am Post subject: Posted: Wed Mar 29, 2006 10:06 am Post subject: |

|

|

just checked the alfa workshop manual for the 145 boxer engine and it states in the overhaul section

"due to the nitriding process it has been subjected to no grinding operations are possible on the crankshaft." |

|

| Back to top |

|

|

Sprintervention

Alfasud

Joined: 30 Jul 2004

Posts: 60

Location: York

|

Posted: Wed Mar 29, 2006 12:00 pm Post subject: Posted: Wed Mar 29, 2006 12:00 pm Post subject: |

|

|

Knight,

nice to get some good info from someone who knows a thing or two...

The main bearings are grooved all the way round. Oil is fed from the filter to an oil gallery the length of the block and from there into each main bearing. The crank is then drilled through so that each big end is fed with oil. The two big end at the extremes of the crank are fed by one oil drilling only.

I suspect that most engines are killed by simple oil starvation at the sump, mostly in long corners at high speeds as you have mentioned. hence the dry sumping idea.

Any chance that you (or anyone else for that matter) could do us a sketch of your proposed sump modifications, I have a couple of spare sumps and a welder!

Cheers

Chris

_________________

1987 Alfa Sprint Veloce |

|

| Back to top |

|

|

knight

Guest

|

Posted: Wed Mar 29, 2006 2:49 pm Post subject: sumps Posted: Wed Mar 29, 2006 2:49 pm Post subject: sumps |

|

|

OK so I'm now surprised - the crank is nitrided!........even so, as its confirmed all the main bearings are fully grooved, I would forget about cross drilling, and focus more on welding wings to the sump and making a proper trap-door wet sump system. I will do some drawings over the next day or so, scan them and place them on this thread. as admittedley its hard to take in if you havent seen one.......as they say, a picture says a thousand words!

having taken another look at my 1.7 8v sump.....man its slim!......not good for long corners

You might want to also investigate jacking up the oil pressure by about 0.5 to 1Bar, via placing a 1mm washer or two under the oil pump pressure regulating valve spring. |

|

| Back to top |

|

|

Sprintervention

Alfasud

Joined: 30 Jul 2004

Posts: 60

Location: York

|

Posted: Wed Mar 29, 2006 6:33 pm Post subject: Posted: Wed Mar 29, 2006 6:33 pm Post subject: |

|

|

I think that only the later 16V engines, and all 145/146 boxer engines are nitrided, the 146/7 crank also has rolled/radiused fillets to the bearings, apparently...

Look forward to your sketches, never knew that I could get so interested in sumps!

Chris

_________________

1987 Alfa Sprint Veloce |

|

| Back to top |

|

|

knight

Guest

|

Posted: Thu Mar 30, 2006 2:40 pm Post subject: wet-sumps Posted: Thu Mar 30, 2006 2:40 pm Post subject: wet-sumps |

|

|

OK here goes…….have spent an hour or two constructing these wet-sump modification drawings to the standard alfa boxer sump…..hope you can understand them…..I would recommend using something like 16 to 14 gauge mild steel (1.6-2mm steel) the 14 gauge 2mm may be the better option, as it may be easier to weld, and seal better as its sometimes easy to blow holes through 16 gauge 1.6mm with a MIG welder!......the oil pick-up pipe should be central in the middle of the sump, so you may need to modify and move it……this is exactly how we did the sumps on the 2001-2003 Proton Impian BTCC engines, on countless other rally and circuit racing engines, and it works a treat, the theory of operation is actually really simple!…....let me know if you have any more questions.

|

|

| Back to top |

|

|

Serpent33

Alfa Sprint

Joined: 06 May 2003

Posts: 210

Location: Singapore

|

Posted: Mon Jul 03, 2006 6:45 pm Post subject: Posted: Mon Jul 03, 2006 6:45 pm Post subject: |

|

|

You mean you engineered for Proton in BTCC races? Hey, you know Farrique from Petronas that races it? He's an Alfisti. BTW. Thanks. I am using your sump info. Cheers!

_________________

Each time I speed I say, "Dear lord, make me fast and accurate..." |

|

| Back to top |

|

|

|